Professional, Experienced & Safe

Here's a few testing & install projects we’ve completed

Successful IPSL Outcomes

Specialised Equipment—Experienced Staff—Industry Knowledge

Scope:

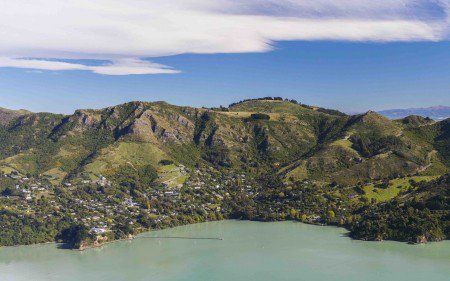

This was an extensive project upgrading the water and wastewater systems throughout the Lyttelton Harbour, with many different stages. IPSL was contracted to test diverse pipework to defined standards using specific procedures.

In addition to testing IPSL was required to:

- Demonstrate their capability by producing comprehensive pre-test procedures, plans, and methodology.

- Show ability to meet Health and Safety Standards

- Provide detailed reports documenting process and results

Challenges associated with this project included:

- The massive scale of the entire overall project

- Working with numerous contractors

- The requirement for essential, specialised equipment

- The highly technical nature of the contract requiring experience and expertise including very complex test calculations.

Action:

IPSL produced documentation demonstrating their capability including:

- A detailed Construction Execution Procedure (CEP) specifying requirements, method, strategy, schedule, and scope of works. This incorporated:

- Project Execution Plan

- Inspection and Test Plan and Checklists

- Job Safety and Environmental Analysis

- MDC Quality System

- Safety, Security and Environmental measures to ensure best practice delivery.

- Job Safety and Environmental Analysis

Final Pressure Testing for wastewater pipes of all project sections was conducted.

Result:

Work was performed to specifications by IPSL for every contracted stage of this large project. The execution of tests in a safe, professional, timely manner, by competent personnel, meant that IPSL played an important role in contributing to the overall project success. All test were completed without harm to personnel, property or the environment.

The details of some of these contracts are outlined in the following three case studies.

Scope:

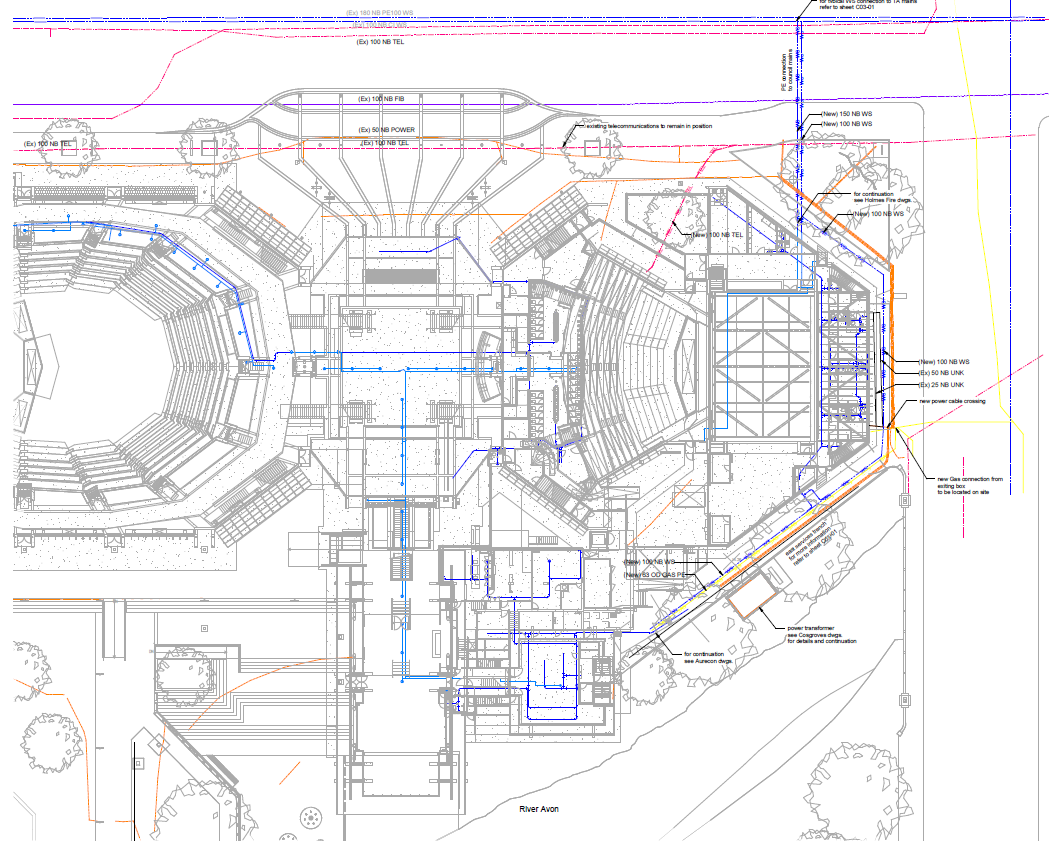

IPSL was engaged to execute final pressure testing for extensive wastewater pipelines covering over 10km on land and under the ocean in the Lyttelton Harbour Basin including:-

Onshore Field Pressure Tests for:

- NavalPoint to Simeon Quay

- Simeon Quay to Lyttelton Tunnel connection Point

- Simeon Quay to Lyttelton Wastewater TP DI &PE

Submarine Field Pressure Test:

- Governors Bay Pipeline

- Diamond Harbour Pipeline

The Submarine Sections were particularly technically difficult including:-

- The purging of air from the lines.

- Environmental factors such as the tidal influence on the external water pressure.

Action:

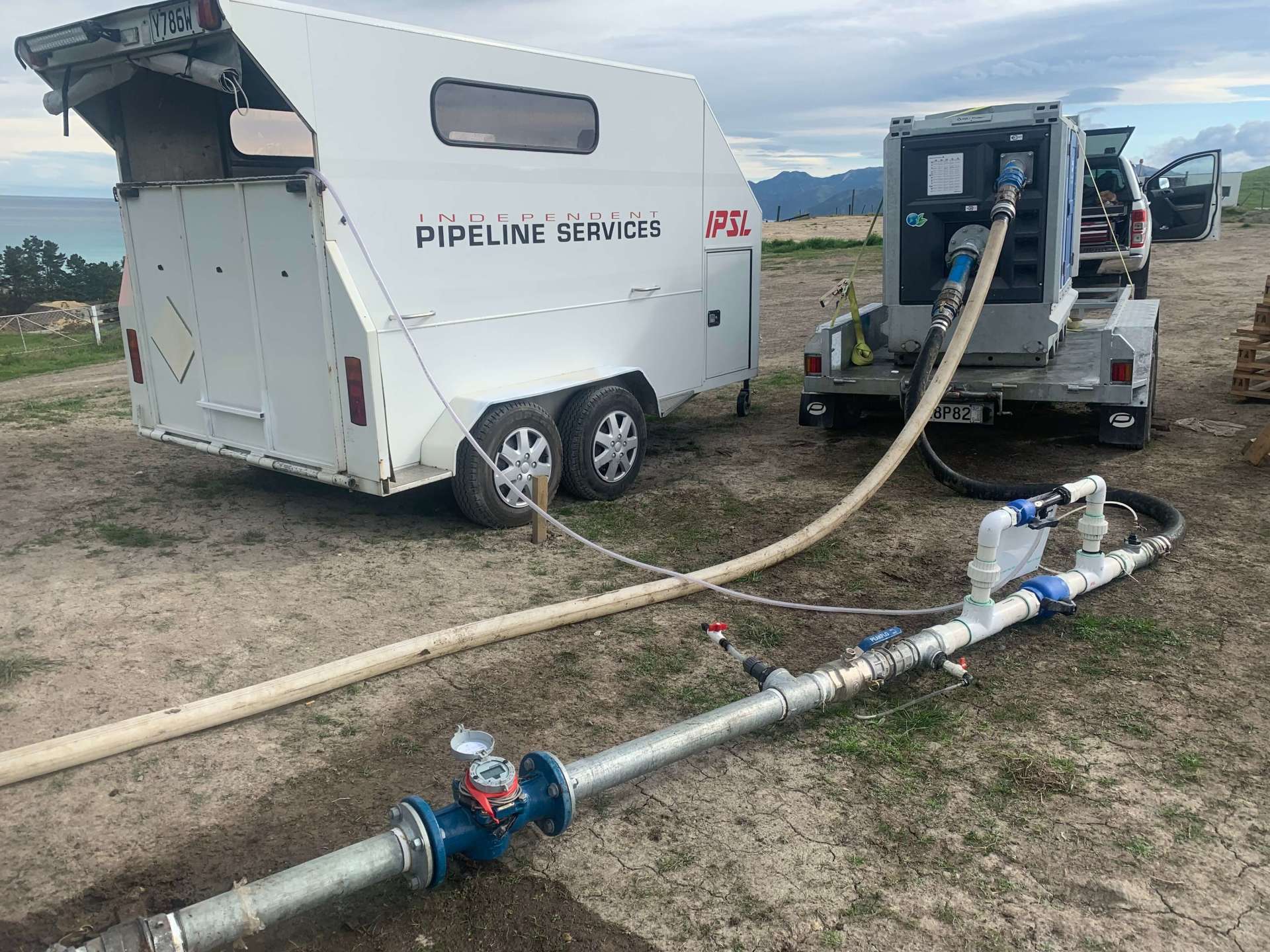

The underwater pipe sections were initially pre-tested on the land. They were then dragged out into the ocean by barges, weighted down and sunk onto the seabed for in situ testing.

The technical issues were accommodated by precisely monitoring the test timing and pressures, then calculating and compensating for the tidal external water pressure variation.

Result:

IPSL conducted In-situ hydrostatic pressure testing allowing the wastewater pipes to comply with CCC CSS Part 3 Utility drainage regulations.

Scope:

IPSL was contracted to decontaminate two reservoirs and deluge pipework, above the Heathcote end of the Lyttelton Tunnel, to meet council requirements for commissioning. The treated volume was approximately 1430m3 (1,430,000 litres).

IPLS was required to implement the chlorination and dechlorination sterilisation process and provide documentation of compliance testing and reporting.

Action:

IPSL calculated and implemented required chlorine levels for effective sterilisation of the reservoir and deluge pipes. These were then decontaminated through dechlorination.

Specialised equipment was used for chlorine level testing at each stage of the procedure.

Full reporting of procedures and test results were compiled providing documentation to meet council regulations.

Scope:

IPSL was contracted to perform pressure testing of the fire hydrant and fire sprinkler pipework, throughout the length of the Lyttelton Tunnel, to meet safety standards.

This involved accessing the complex of pipework through the maintenance passageway of the tunnel.

Some of the technical challenges associated with this project were;

- The vast range of large scale pumps required to test the varied pipework for the system, and

- Pressures outside of the normal range because of the project elevation

Tunnel closure and traffic control were required to minimise disruption to traffic while implementing for safe, efficient pressure testing.

Action:

IPSL conducted pressure testing over 2km of DN300mmm stainless steel and steel pipework. Measurements were performed with highly specialised equipment and gauges.

The project was implemented in several stages with work done at night to maximise traffic access through the tunnel.

Result:

Pipework pressure testing carried out safely and efficiently by IPSL with supporting documentation to verify the met regulatory standards for the Tunnel fire hydrant and sprinkler system.

Water Pump Stations Wellhead Security Improvement

Christchurch City Council

Scope:

To maintain the safety of Christchurch’s drinking water, the City Council implemented a new wellhead improvement system. This involved replumbing water pump station casings with new pipes.

IPSL was engaged by the majority of firms contracted for the project, to pressure test and disinfect most of the new and upgraded wellheads.

Action:

IPLS performed pressure testing, chlorination, flushing and bacteria testing of new wellhead pipeworks and fittings on over 30 of Christchurch’s drinking water wells.

Wastewater System Leak Identification & Location

Scope:

IPSL was contracted to check over 7km of Wastewater PE pipeline, replaced as part of the Christchurch rebuild infrastructure project. When pressure testing indicated a major leak, IPSL was engaged to determine the leak location.

IPSL used traffic management and conducted the pressure testing at night to reduce traffic disruption.

Action:

IPSL used specialised acoustic leak detection equipment. They attached pumps at various points on the pipeline and monitored flow meters on the leak detection equipment. Through real-time communication between staff they accurately narrowed the area of the leak locations.

Their expertise of the IPSL team enabled them to detect small discrepancies, and determine the precise location of issues. Their knowledge of the pipe system and understanding the impact of different pressures and volumes on test readings was critical in the successful outcome.

Result:

Two major leaks were rapidly identified, the location pinpointed to within a meter over 7 kilometres of pipeline, saving their client significant resources. The contractor would have had to invest a massive amount of additional time and money and equipment if they were to attempt to discover the leak themselves. Client was so very grateful they even queried if they had been invoiced correctly.

The contractor was so impressed they contracted IPSL for another job on the West Coast. IPSL worked all night in Greymouth for two nights using their acoustic equipment and determined a leak location within a couple of meters over 7km of pipeline.

South East Halswell Wastewater Scheme

Blakely Construction

Scope:

Blakley Construction had laid eight kilometres of new pressure sewer-mains pipes, and constructed a new pump station in Sparks Road, to accommodate growth in Westmorland, Halswell and the new subdivisions in the area. The large volume capacity and high pressures associated with this sizeable project made pressure testing the new pipework to meet regulations difficult. The project was also under urgent time constraints to complete the Nga Puna Wai section for the construction of the new sports hub.

Action:

IPSL pressure tested over 3.2 km of high-pressure DN400 diameter PE pipeline and the linked pump stations for Blakely Construction to ensure they safely complied with regulations.

Result:

All portions of work carried out on this project by IPSL was completed to project specification, on budget and on time. The pipeline was commissioned for the South East Halswell Wastewater Scheme.

Temuka Water Main Trunk Pipeline

Timaru District Council

Scope:

IPSL’s services were contracted by the Timaru District Council for an urgent, multimillion-dollar project replacing the trunk water-main pipeline for the town Temuka.

The District Council was facing a major problem. The existing water main had been leaching asbestos, requiring it to be replaced immediately. A new main pipeline had to be constructed and commissioned as soon as possible Consequently three separate contractors were engaged simultaneously.

IPSL worked with the Timaru district council and three different contractors to complete the scope works in an extremely short timeframe.

Action:

IPSL filled, flushed, pressure tested, chlorinated and dechlorinated approximately 9 km of new DN 500 PE water mains.

Result:

IPLS contributed a small but crucial role in the successful completion of this project by being in the right place at the right time when timing was critical. They pulled out all the stops to complete the scope of work in a very tight time-frame. Their ability to coordinate with the Timaru district council, and the three different contractors, on multiple worksites helped the project remain on schedule.

All IPSL portions of work carried out on this project was completed to project specification, on budget and on time.

The rapid, successful completion and commissioning of this water main trunk pipeline enabled the town residents to come off severe water restrictions and access plentiful safe drinking water.

Sheffield Central Plains Water Irrigation

Fulton Hogan

Scope:

Fulton Hogan had undertaken the construction of an extensive irrigation system to bring irrigation and stock-water to around 30 farms on the Sheffield Central Plains. IPSL was contracted to conduct pressure testing of this system.

This massive scale project entailed: -3 7 km of pipeline, 31 irrigation turnout assemblies, 7 pump stations including the main pump station intake from the Waimakariri River.

Some of the significant challenges involved in this project included:

- The huge variation in pipe diameters, ranging from 200mm to 1.8M causing difficulty managing pressure variation measurement

- Sheer size- normal pressure monitoring equipment wouldn’t work

- The completion of the project under time constraints as was necessary for it to be complete before the dry season

- Sourcing water to fill the pipelines for pressure testing was a particular problem as the main pump station was still under construction.

Action:

IPSL pressure tested the entire irrigation system for Fulton Hogan. A fire engine, specifically designed and adapted for the project by IPLS, was used to pump water from the Waimakariri to fill pipelines for pressure testing .

They were able to identify and locate leaks in the 37 kilometres of irrigation pipeline that were able to be repaired.

Scope:

IPSL provides testing and treatment of subdivision pipelines for developers and contractors to meet council regulations and safety requirements.

These are frequently subdivisions with extensive pipeline networks. The pipes are often made from different materials and range in diameter from 20mm to 300mm, impacting on pressure measurements.

IPLS’s expertise and wide equipment range are required to accommodate the variation in the pressure testing process.

Action:

Subdivisions projects include:

- Testing and treatment of pipework system for each stage development

- Pressure testing

- Chlorination process

- Sterilisation testing

Examples:

- Faringdon: Contracted by BG Contracting & Blakely Contracting.

- Rangiora: Contracted by Tru-Line Civil to test and treating water pipeline for the Townsend Road extension.

- Southbridge:

Contracted by Utilities Infrastructure for the High St subdivision.

Result:

IPSL demonstrates, for each of these clients, that they deliver on what they promise they will do.

For each subdivision, IPSL performed their contracted work, meeting project specifications, on budget, and on time. This enabled clients to demonstrate compliance with council regulations and safety requirements.

Commercial Fire Sprinkler Systems

Scope:

Fire Sprinkler Systems are an essential safety feature of all commercial buildings. IPSL pressure test pipelines from the town’s main water supply to the buildings Fire Sprinkler Systems enabling owners to demonstrate critical Health and Safety compliance.

IPSL is able to perform pressure testing on all Fire Sprinkler System pipelines adapting varying pressures and using different test methods relating to the pipe material and size.

Action:

Pressure testing of fire sprinkler systems for a huge variety of clients including:

- Schools:

- Lincoln University

- Christchurch Boys High School

- Sydenham Primary School

- Spreydon School

- Christchurch Girls High School

- Canterbury University

- Beckenham Primary School

- Ara Polytechnic

- Te Waka Unua School

- Woodend Primary School

- Commercial Buildings:

- Christchurch City Library

- Te Puna Christchurch Convention Centre

- St Albans Retirement Village

- Foodstuffs Papanui

- Riccarton Mall

- Justice Precinct

- Christchurch Town Hall

- Rolleston Prison

- Metro Centre

- Christchurch Hospital

Result:

In each case, IPSL executed its services to specifications, budgets, and time frames to meet compliance for Health and Safety regulations as determined by an independent advisor.

Reservoir Testing & Sterilisation

Scope:

IPSL conducts pressure testing and sterilisation of reservoirs and all associated pipework systems.

They have the ability, experience, and knowledge to efficiently execute all the necessary procedures. This involves a significant complexity as every individual reservoir requires a specific step-by-step methodology to be prepared and documented. The process also requires specialised equipment that is used purely for reservoirs.

This expertise allows IPSL to deliver reservoirs, sterilised, and sealed free of contaminants that meet all regulatory standards. IPSL plays a crucial role in enabling the reservoirs to be safely commissioned on time.

The details of some of these contracts are outlined in the following two case studies.

A: Helpet Park Reservoir, Rolleston Water Supply

Blakely Construction

Scope:

Blakely Construction was contracted to build a new reservoir in Helpet Park, Rolleston, including the internal pipework and external drain lines.

IPSL was engaged to perform the testing and sterilisation of the reservoir and pipelines including the pump station, UV treatment plant, and filter.

This was a time-critical project as the reservoir needed to be commissioned as soon as possible.

Action:

Not only did IPLS implement all procedures to specification to meet the required regulatory standards, but they also developed a unique methodology for the chlorination and dechlorination of this new reservoir without interrupting the incoming pipework.

They provided a highly efficient solution by injecting chlorine via a dosing unit linked to a flow meter on the input pipes. This enabled a variable rate dose of chlorine to be delivered as required. Because these pipes are linked to the well and pump stations that feed the reservoir, the entire water supply network is ultimately treated efficiently and cost-effectively.

Result:

IPSL played a critical part in allowing the reservoir to be commissioned in a timely and cost-effective manner.

B: Kaikoura Reservoir

Arc Projects

Scope:

IPSL was engaged to execute testing and sterilisation of a reservoir and the related pipework, constructed by Arc Projects, in Kaikoura.

Action:

IPSL performed the testing and chlorination efficiently using a specialised portable flow meter and dosing unit.

For this project, they implemented a process diverting the water flow by disconnecting the outlet pipe and circulating it back to the reservoir via a pump.

Result:

The reservoir was able to be commissioned on schedule.